Single hose air conditioners can't cool a room: Convert them to dual hose

Single hose air conditioners (AC) should be banned. By design, they are inefficient; they can blast cold air at a person sitting directly in front, but will never be able to cool the rest of the room. Single hose ACs are bad news for the environment, energy bills and your heatwave comfort!

The problem for UK residents is that single hose ACs are the only type of portable model availabl. Dual hose models, window units or portable split units are not available, despite their superior performance and efficiency.

But what makes single hose ACs so bad?

Background: Air conditioners are refrigerators with fans

Most air conditioning systems work by exchanging heat from the inside air to the outside air, using vapor-compression refrigeration. All efficient designs (anything that’s not a single hose) do this without ever mixing the separate air masses or causing any pressure differential between the outside and inside. It doesn’t matter whether it’s a split AC unit in a commercial property, the AC in your car, or your kitchen refrigerator, they follow this operating model:

Dual hose portable air conditioners are perfectly fine too, as they follow the same principles. The only difference is that they incorporate the outside unit into a single inside unit; instead using ducting hoses to draw outside air over the condenser coils and back to the outside again. They are more convenient as no permanent installation is required. They are marginally less efficient due to heat loss through the hoses and the additional heat generated from the compressor, which is now inside the room that needs to be cooled.

What makes single hose ACs so bad?

Single hose models are the only type that violate this principle, which is why they are so inefficient. Instead of using two hoses to keep the air masses separate and drawing outside air to pass over the condenser coils, they ditch the intake hose and just draw the inside air instead — destroying the working principles of air conditioning. Why? Probably because it’s easier to market and sell the convenience of one hose rather than two. They forgot to mention in the fine print that having only a single hose makes the machine close to useless.

This single hose design has a huge performance cost. With the inside air now being forced to the outside through the exhaust hose, the inside is now always at a lower pressure. No room is perfectly sealed, so to equalise the pressure, hot air from outside is continuously drawn through door frames and a multitude of other tiny gaps in the room. This is why single hose units will never cool an entire room, they are constantly fighting against hot air rushing back into the room due to the negative pressure.

Don’t believe me? Turn the AC on in a small room, use a good seal between the exhaust hose and the window, then close all doors and feel around the gaps between the door and the frame. You’ll be able to feel the air rushing in to the equalise the negative pressure in the room you’re trying to cool.

Don’t believe me still? Leave your AC running for an hour, then come back in the room. You’ll be dissapointed. Walk round the edges of the room, it’ll feel barely cooler than when you left. Touch the walls, they’ll be warm still. In any other setting like an office, restaurant or car, you’re used to the whole room being cool, not just the tiny space directly in front of the air conditioner.

Solution: Convert the single hose AC to dual hose

Thankfully, many single hose ACs can easily be converted to dual hose systems. Single hose systems are often designed with two separate intake ports just like dual hose units, despite only needing one; it’s like the engineeers knew that a single hose was a bad idea so left in the ability for modification. By fashioning an adapter to duct the condenser intake port so that it draws from the outside air, it will perform with the same efficiency as a dual hose unit.

WARNING

I am not an expert on air conditioners, safety or anything related. You must be aware that you are following instructions from some random person on the internet that spent 20 minutes with cardboard, duck tape, trial, error and some luck. If you choose to try it, you are doing so completely at your own risk.

Some important warnings:

- Overheating risk: This modification might increase the risk of the unit overheating, especially if modified incorrectly. It is easier for the ducted intake hose to become blocked or the flow rate impaired, compared to a wide open grille that was present before. If you are ducting, make sure to not introduce any flow restrictions.

- Fire safety: Buy an additional fire alarm to have in the room with the AC. It is likely the room with AC will have the doors closed. If you fall asleep and the machine malfunctions, it'll take seconds for the smoke to fill the room. With the doors closed, it's likely that you'll have already taken in too much smoke to wake up before it's able to reach the normal fire alarms outside the room you're in. You've spent a lot on an AC unit, spend a little extra to make sure you have a fire alarm in the same room as you.

- Warranty: It will almost certainly invalidate any manufacturer warranty.

- High temp materials: Materials used in the conversion must be able to withstand the same high temperatures as the exhaust hose, just in case they accidentally come in contact.

Will this work with my AC? The flow block test…

Every AC unit is different, so there are no guarantees this modification will work with every model. As a guide, there are two major requirements that an AC unit must meet to make conversion possible:

- The machine must have internal separation and air tight seals between the evaporator and condenser air flows.

- There must be two separate air intake ports, one for the evaporator (cold out) and one for the condenser (hot exhaust) air flow.

There’s a quick way to check whether both requirements 1 and 2 are met, and also establish which intake needs ducting — I call it the flow block test:

- Attach the exhaust hose and turn the unit on. Keep the hose inside the room with you.

- Using a sturdy but flexible item in one hand, such as a magazine or cardboard cutout (something strong enough to not get sucked in), temporarily block one of the air intakes while the machine is running. Don’t do this for more than 2 seconds at a time, because you might burn the AC fan motor out with the extra stress.

- Use your other hand to check the flow rate changes as you block the intake.

To pass the test, when the intake is blocked, both:

- The air flow rate out the exhaust hose must significantly reduce, or stop entirely.

- There must be no change or reduction to the flow rate of air exiting the cold air output grille.

- If both of those flow rate tests pass, then congratulations the machine can be converted, and you’ve just found the intake that needs ducting to the outside with an extra hose.

An additional minor requirement is that thermostat temperature probe must be on the evaporator (cold) side air intake/flow also. This usually looks like a small plumb bob dangling in front of the evaporator (cold) coil fins. The trouble comes if the probe is located in the condenser (hot) side air intake, because once the intake is ducted it will no longer measure the room temperature, it’ll measure the outside air temperature. This means that the unit can never tell when the room has reached the correct temperature and will always call for more cooling. Aside from your room ending up like a fridge, this also increases the risk that the unit could overheat, because the compressor never switches off as never detects the room is cold enough.

Instructions for conversion after flow block test

If all machine requirements are met, you should once again read, be aware and mitigate the risks mentioned in the red warnings box further up on this page.

Once aware of the risks, the steps to convert the unit from single hose to dual hose are simple:

- Buy an additional fire alarm to have in the room with the AC. I’m not joking about this.

- Source an additional air conditioning hose or equivalent. This should be a similar diameter to the exhaust hose, so that flow rate is not restricted. It’s also important it is sturdy and suitable for high temperatures, as this will be used partially outside in the sunlight on hot days.

- Create an adapter to duct the condenser (hot) air intake that you identified earlier, into the additional air conditioning hose, so that it draws air from the outside instead of inside. Make sure it’s a good seal.

- Place the new hose through to the outside along with your exhaust hose

- Ensure there is enough distance so that the hot air of the exhaust isn’t being drawn straight into your new intake.

- Secure the outside part of the intake hose. If left dangling, the suction could draw it onto close objects and block the flow. I found this out through experience, one day my intake hose had stuck itself to the outside wall like a limpit.

How will I know if the conversion worked?

Place both hoses out of the window, ideally with some separation between them, then turn the unit on. An AC window sealing kit is a worthwhile addition - search for AC window sealing kit, they’re about £20.

Close all of the doors and other windows, then do a quick feel with your hands (or face) around the door frames. If you can’t feel any air rushing in, then you’ve ducted the right intake and there is no longer a pressure differential in the room.

Then leave the room for at least an hour. Even if the conversion was successful, a perfectly functioning AC will still take a while too cool a whole room down due to the latent heat in all of the furniture and walls. After an hour, the room should have started cooling down. After many hours, everything in the room should be cool to the touch and feel like a fridge.

Further tips for optimum efficiency

- Purchase a window sealing unit designed for your type of window. They’re only around £20, but make a big difference to the cooling performance, plus keep those summer bugs and flies outside.

- Keep the intake and exhaust hoses away from each other when outside of the window. Having them close to each other increases the chance that the hot exhaust air is being drawn straight into the intake hose. If stacking vertically, I like to keep the intake hose below the exhaust hose for this reason too, as hot air rises slightly.

- Keep the length of the hoses short, to minimise losses back into the room. Move the unit as close to the window as possible.

Known working AC model conversion examples

Challenge 5K (5,000 BTU)

This is the first air conditioner I modified. The unit was purchased in 2019 for £289.99 from Argos. Despite only being 5000 BTU, after conversion to dual hose it was able to cool a medium sized room from 34 C outside temperatures down to 22 C in only a couple of hours.

The conversion was performed in minutes, using items easily purchased at a hardware shop or found around the house:

- An additional air conditioner hose bought from Amazon.

- An old clear tupperware box that was about the same size as the condenser intake port.

- Spare foam strips that came along with the air conditioner to provide a better seal between the box and the unit.

- Plenty of duck tape.

On the Challenge unit, the condenser air intake is the lower grille underneath the exhaust hose port. After ducting this grille into the tumble drier hose, this is the result. Not aesthetically pleasing, but very effective for the three days of summer that the UK gets every year:

Originally, I acheived this using a polystyrene box, carboard and a tumble drier hose. Whilst it worked fine, this wasn’t the safest approach so next time I used a proper air conditioning hose and a sturdy tupperware box:

Delonghi Pinguino EX120

Robbie has successfully converted the Delonghi Pinguino EX120 Silent 11500 BTU Portable Air Conditioner. The lower rear grille was ducted to acheive this:

Matsui MAT-7KACW

Matthew has sent in a guide to their successful modification of a Matsui MAT-7KACW:

Dual Hose Adapter

I tested the vents to confirm that the bottom vent under the existing hose was the correct one to attach to.

I measured the dimensions of the vent and screwed together a frame out of wood that size. I drew around the frame onto some plywood and cut it out with a handsaw.

I attached the plywood to the frame with a hammer and some pins and some no more nails. I then drew around the hose adapter for the vent side onto the ply and cut it out by drilling holes and using a jigsaw. I screwed then hose adapter to the wood.

I lined up the rear plastic vent with the wooden frame and marked the screw holes. I used longer screws of the some size and thread to attach the wooden frame to the air conditioning unit through the plastic vent and existing mounting holes.

I attached the pipes to connect the new wooden frame 2nd hose adapter to the window kit. And the existing hose point to the window kit.

Including a custom made window kit, which looks very sturdy!

Window Kit

I measured the dimensions of my window and cut a piece of plywood with a handsaw such that it would block my window.

I then drew around the end of the 2 hose adapters, drilled holes then used a jigsaw to cut them out.

I then measured the depth of my window and cut blocks of wood of approx that depth. I drilled a hole through another pieces of wood and then drilled them together to create the locking mechanism to hold it in place.

It’s fitted with the blocks turned inwards, and our out of the window narrow side first, then rotated and brought up into the window slot, the blocks are then rotated to overlap with the window frame and secure it.

The hose adapters and screwed into the plywood and left attached. The hose is removed from this as and when needed.

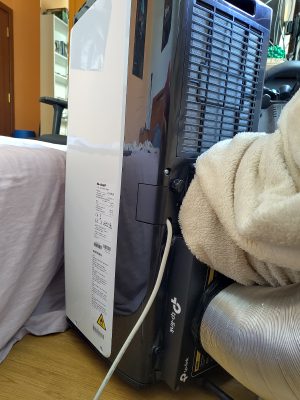

Sharp CV-H9XR

Klis has sent in this modification of a Sharp CV-H9XR:

I got a Sharp CV-H9XR, hoping to make the room habitable, but all it was doing was creating a slightly cool pocket in one corner of the room while making the rest of it even hotter. Also, since I have a casement window, I needed a sealing kit, but the pressure in the room was so low because of the AC, that it kept ripping the seal away from the frame.

A few days ago I looked online for what I can do about it and found your article. I decided to try it out and lo and behold, it actually worked! I had some issues, because the unit actually has two intakes, one on the back and one on the side, but with some cardboard and an ungodly amount of duct tape I bridged the two grills and connected them to the outside with an aluminium pipe from the local home improvement store.

Converted your model successfully?

If you’d like to help others and include a picture of how to convert your specific model on this page, please get in touch using the contact details on the about page.